Automatic Horizontal Baling Press Machine

A Baler Frontier With almost 40 years of Industrial Balers Experience In Taiwan - Custom Designed Balers and Recycling Equipment for Industrial Cardboard, Paper and Plastic Waste.

Techgene Machinery is a recycling baler manufacturer who's been in the recycling industry for almost 40 years. From the paper box, shredded paper and cardboard balers to the plastics, can and aluminum recycling balers.

Automatic Horizontal Baling Press Machine (TB-091140)

Machine Alias Name

Baling press, scrap baler, baler equipment, recycling baler, waste baler, baler manufacture, paper baler, cardboard baler, recycling equipment, baler Manufacturers and Suppliers from Taiwan, China, Asia and Worldwide.

Automatic Horizontal Baling Press (TB-091140) for Baling press, scrap baler, baler equipment, recycling baler, waste baler, baler manufacture, paper baler, cardboard baler, recycling equipment, baler

Product Details

TB-091140 Automatic horizontal baling press is suitable for the recycling collectosr and paper manufacturers, printers, paperboard factories, especially for those with large space and high outputting demand. There are many kinds of materials can be compressed by TB-0911SERIES, including scrap papers, cardboards, carton boxes, newspapers, magazines, plastic films...etc.

This paper baler has 5~7 tons per hour capacity and can make the bale size reach to 1050mm width and 750mm height (Variable Length), its bale weight can up to 700kg. There is a hopper to be set in the middle of the recycling machine in order to feed in the waste material. Customers can choose a appropriate feeding way such as feeding through air cyclone, conveyor, excavator or manual. The shape of hopper also can be customized to fit the way of feeding. The main feature of this baling press is initiative twin -cylinder and trouble-free isolated twisters, which can tie the bale automatically and make the user to operate it easily. Also the operation and monitoring function are controlled through a programmable logic controller (PLC).

Techgene Machinery manufacturs the scrap baler with strong and rigid structure which is reliable and optimum for less maintenance.

Model

| MODEL | pressing Force | Motor | Wire Tie | Capacity |

|---|---|---|---|---|

| TB-091140 | 65Tons or 80Tons | 40 HP (30KW) | 4 Horizontal | 5~7Tons/Hour |

Specifications

1.Bale Size :1100mm(W) x 750mm(H) x 2000mm(L)(length is adjustable)

2.Max. Throughput:4~6 Tons/HR (depending on the bulk density of infeed paper)

3.Bulk Density :45~55Kgs/M3

4.Bale Density :400~450Kg/M3 (depending on the materials)

5.Bale Weight :Approx. 700 Kg (bale length at 2000mm)

6.Pressing Force :65 Tons (Φ200) or 80 Tons(Φ225)

7.Specific Pressing Force:77N/cm2 (Φ200) or 95N/cm2(Φ225)

8.Loading Aperture :1036mm(W) x 1665mm,2000mm or 2400mm(L)

9.Electric Power :( )V x ( )Hz (please confirm)

10.Driving Motors:Hydraulic Motor : 40HP x 1 PC

Twister Motor : 1HP x 1 PC

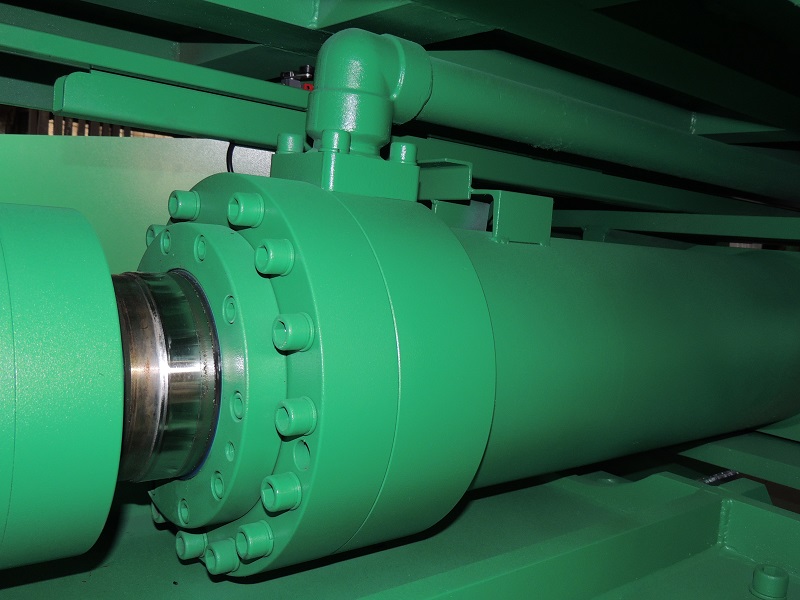

11.Cylinders :Main Ram Cylinder : Φ200 or Φ225 x 1 PC

Side Neck Cylinders : Φ165 x 2 PCS

Top Neck Cylinder : Φ150 x 1 PC

Inserter Cylinders : Φ63 x 2 PCS

Wire Cutter Cylinder : Φ40 x 1 PC

12.Hydraulic Pump :Denison

13.Hydraulic Oil :#68 Hydraulic Fluid Oil

14.Oil Tank Capacity :Approx. 1000 Ltrs.

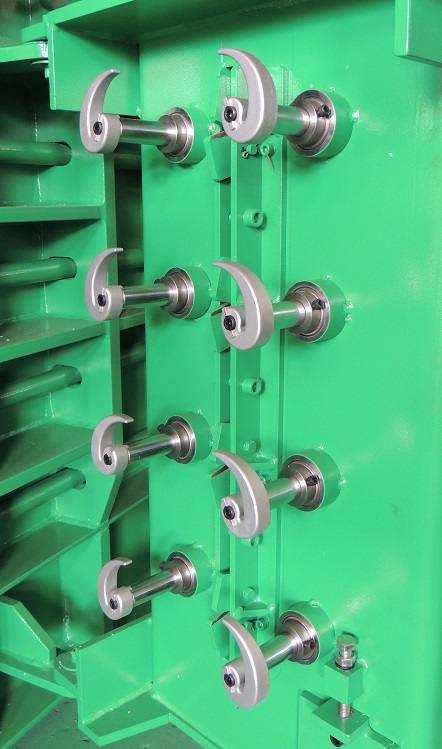

15.# of Wires : 4 strapping wires traversed

16.Baling Wire : 2.8mm Dia. twice annealed wire

17.By 3 ways output neck press for equal press on materials.

18.Applied PLC for control function of machine.

19.Hydraulic regenerative circuit system.

20.Hydraulic oil is cooled by fan cooler or water cooler.

21.A temperature detecting system controls the temperature of hydraulic oil.

22.Low oil level alarm system is to avoid danger of air sucked by pumps.

23.Bale length coordinating control system

24.Ball joint for connecting platen with ram cylinder, and swingable cylinder supporter for enduring life.

25.Multi-Stage paper shear-off.

26.Inserters are driven by exclusive twin cylinders for reliable operation and flexible adjustment.

27.Included 2 sets wire feed roller clothespole.

28.Photoelectric cell control in feeding hopper.

29."Proface" touch screen to show clearly all operation status.

30.Working hour meter and bale quantity counter (subtotal and grand total).

31.1-year warranty under proper maintenance and normal operation.

32.Included standard spare parts, tools for general use and English operation manual.

Features

- Factories especially with high capacity demand and large scale.

- Can compress larger papers such as carton boxes, corrugated papers, cardboards.

- Press force from 65~80 tons, capacity from 5~7 tons per hour

- Bale size is 1050(W)*750(H)*Variable (L), Bale weight can up to 700kg

- Recommended to equip with automatic ruffler for magazines or newsprints to make bale tightly.

- Can equip the conveyor, air cyclone, excavator to feed the waste materials.

- The position of operation panel and shape of hopper can be modified to satisfy the real demand of customers.

- All operation and monitoring function are controlled through a programmable logic controller(PLC)

- Exclusive auto-tier system

- The strong and rigid structure is reliable and optimum for less maintenance.

Other Innovative Baling Press Machine Design

Automatic Horizontal Baling Press Machine(TB-091180)

Automatic Horizontal Baling Press (TB-091180) for Baling Press, Automatic Hydraulic Baling Press, Automatic Scrap Baler, Horizontal paper scrap scrap

Automatic Horizontal Baling Press Machine(TB-091160)

Automatic Horizontal Baling Press (TB-091160) for Automatic baler, baling press, Baling Press, Automatic Hydraulic Baling Press, Automatic Scrap Baler, Horizontal paper scrap scrap

Automatic Horizontal Baling Press Machine(TB-091140)

Automatic Horizontal Baling Press (TB-091140) for Baling press, scrap baler, baler equipment, recycling baler, waste baler, baler manufacture, paper baler, cardboard baler, recycling equipment, baler

Contact Techgene Now!

Next: Automatic Horizontal Baling Press Machine(TB-070840)

Previous: Automatic Horizontal Baling Press Machine(TB-091160)

ARTICLE SECTIONS

- A Baler Frontier With Almost 40 Years of Baling Machine Experience In Taiwan - Pack Exceeds Your Expectation

- Waste Baling Machine Supply - Techgene Machinery Co., Ltd.

- Plastic bottle recycling baler manufacturer – Techgene Machinery

- Recycling Baler Successful Cases From Techgene Machinery

- Success Recycling Equipment Stories - Great Auto Tie Baler Experience

- TB-1011 SERIES. TB-0708 SERIES Horizontal Baler - Innovative Baling Machine Design

- Horizontal Baler, Vertical Baler - Customization Design Upon Your Waste Equipment Demand

- We Design To Accommodate Your Baler Plant's Need

- Baling Equipment Sold Worldwide With Innovation

- Contact Techgene Machinery - A recycling baler Expert

- TECHGENE MACHINERY CO., LTD. Privacy Policy

Automatic Horizontal Baling Press Machine - TB-1011 Series

Automatic Horizontal Baling Press Machine - TB-0911 Series

Automatic Horizontal Baling Press Machine - TB-0708 Series

Automatic Horizontal Baling Press Machine - TB-0505 Series

Vertical Waste Baling Press Machine - TVB Series

Cutter Shredder - TSH-1600, CONVEYOR

Close-End Baler - TCB Series

-

Indonesia

- Ms.Irna

- PT. NASINDO SEJAHTERA CEMERLANG

- Jalan Raya Serpong Km. 7, Kawasan Multi Guna Blok B1 No. 10, Pakualam - Serpong, Tangerang 15310, Indonesia

- Tel: +62-21-539 6633

- Fax: +62-21-539 6622

- nasi38sc@centrin.net.id

- Skype: irnaoctaviani

-

Russia

- Mr.Daniil Dubitskiy | Sales Dept.

- Gofro Technology JSC

- Tel/Fax: +7 (812) 777-15-15

- Skype: daniil.dubitskiy

- dan@gofrotech.ru

- www.gofrotech.ru

-

Australia

- Mr.Jeff Goodwin

- Sales Specialist | Environmental Technology Solutions

- DKSH Australia Pty Ltd.

- 14-17 Dansu Court Hallam VIC 3803, Australia

- Phone: 1300 133 063

- Fax: +61 3 9554 6677

- Mobile: +61 438 106 048

- jeff.goodwin@dksh.com

- www.dksh.com.au

-

India

- Mr. C Naresh

- Tel: +(91) - 09380515024

- naresh@subasolutions.com

For LIVE HELP, please click "Live Help Desk", our specialists will be with you in air shortly.

SEARCH PRODUCT